Dodge Dana 44 Crossover Steering System for '72-93 Dodge Trucks, 12" Lift

Crossover Steering Cliff Notes (More info can be found under description)

Crossover steering improves geometry and poor steering characteristics over stock push pull

'77 and earlier Dodge trucks need to swap steering gear boxes for the same application but 2WD instead of 4WD. The steering box needs to be installed in the 2WD location.

'78-93 Dodge trucks can use the existing steering box but it needs to be moved to the 2WD location.

This kit requires either Machining of your flat top knuckle, we offer that service here

(Click to expand)

Why do you need crossover steering?

What is needed for crossover steering?

Why use our crossover steering kit?

What about my sway bar?

Information for 2-3” lifted trucks

Kit Contains

Pitman Arm: (This is the arm attached to the steering box shaft)

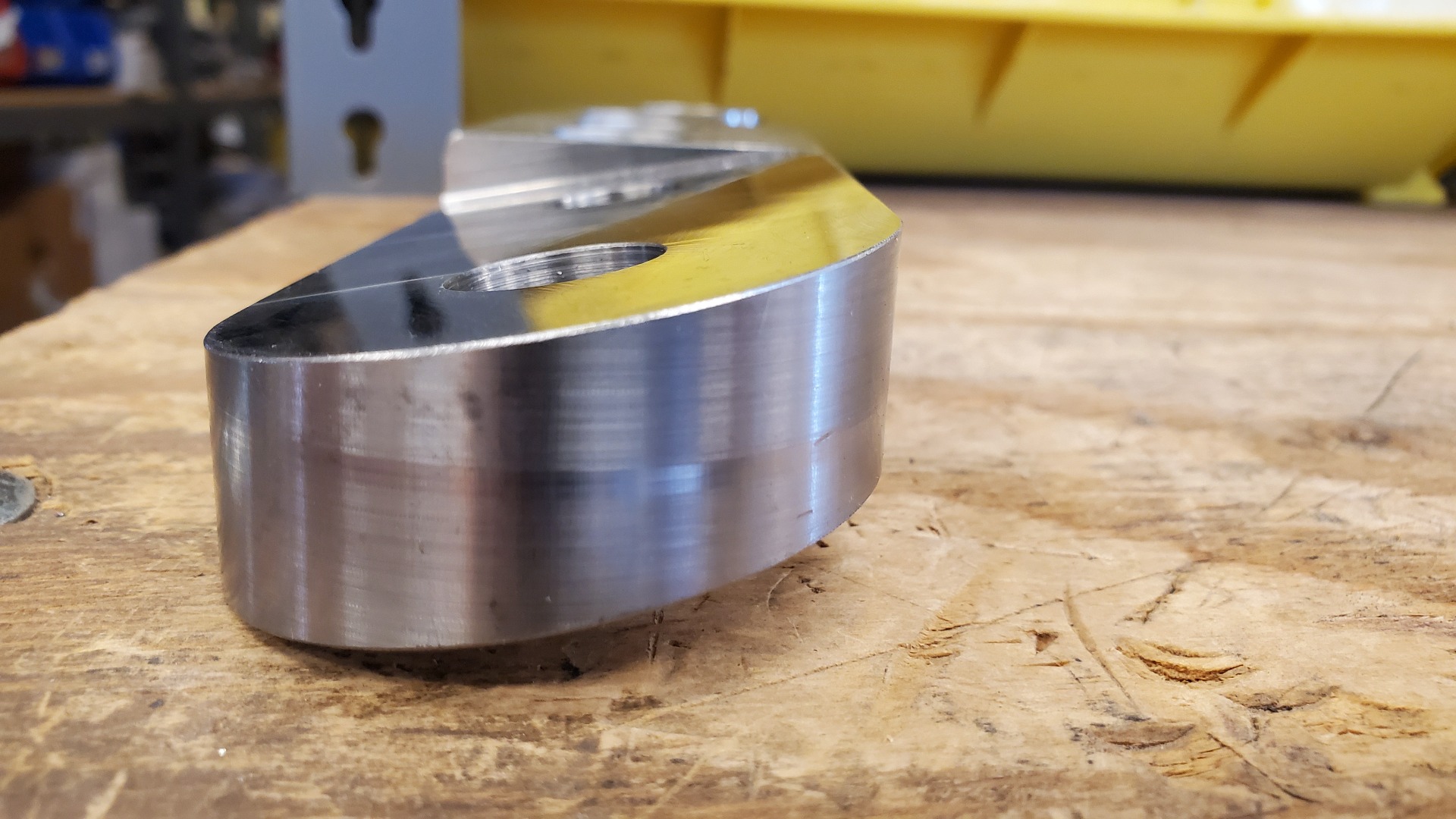

Steering Arm: This is the arm that attaches to the steering knuckle on the axle. It uses factory type studs, cone washers and locknuts to bolt to the knuckle. Our steering arms are tapered for the large GM tie rod ends. These are not the same as the draglink ends, be aware. We can custom build the steering arm with no hole if you wish, or the holes can be drilled out for a heim joint. We've had the best luck with using factory type tie rod ends for steering since they are a better single shear connection and have good service life.

The Offroad Design D44 steering arm end is cut on an angle to correct for the ball joint axis inclination angle and keep the angle on the rod end minimized for best life of the joint and more vertical wheel travel without steering bind. We've attempted crossover steering systems using arms that aren't built with the angled end and the rod end was maxed out at ride height! No droop available at all. This is an essential feature for a properly built fully functional system. 4 tapered holes to work with stock or aftermarket knuckles.

ARP Stud Kit: (Set of 4 ARP High Strength, 190,000+ psi studs)

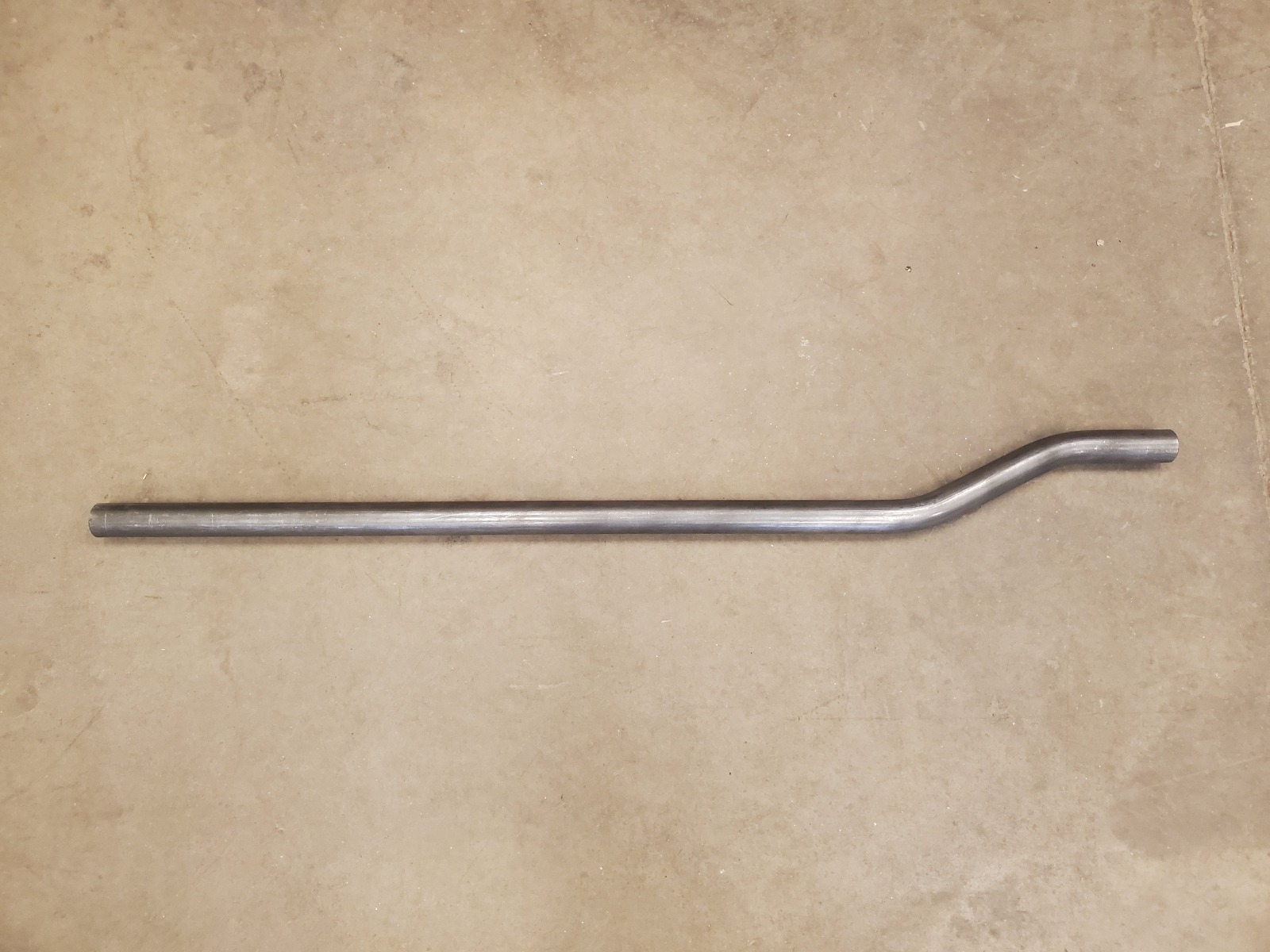

Draglink: (This is the link that ties the pitman arm and steering arm together. We sell the tube threaded on each end with the ends installed)

Tie Rod Ends: (1 LH, 1 RH with jam nuts and castle nuts. These are a new HD end with angle capability similar to a GM draglink end but with the short strong shank of a tie rod end.

Our tie rod ends are manufactured specifically for us. Factory GM draglink ends have good angle capacity, but have long shanks that can cause clearance issues. Factory GM tie rod ends are nice and short, but have very little angle capacity. Our ends are built with the best of both worlds, this is crucial in many applications (particularly 67-87 GM straight axle trucks) as many times the bend in the draglink has to start as soon as possible to clear the engine crossmember, the extra shank on draglink ends makes that impossible.

Additionally, our tie rod ends are a metal-on-metal design with a preload spring on the bearing race (sort of like the upper kingpin on a Dana 60), that helps keep the joint tight even as the parts wear.)